Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

This article delves into the fascinating manufacturing process of glass bottles, outlining the journey from raw materials to the finished product. You'll learn how various types of glass bottles, such as beer bottles, beverage bottles, and even uniquely designed custom glass bottles, are made and subsequently packaged.

1 – Raw Materials for Glass Bottle Manufacturing

The primary raw materials for manufacturing glass bottles are sand, soda ash, and limestone. Cullet (crushed recycled glass) is added to this mixture. Cullet can be waste from the manufacturing process itself or from recycling centers. For every ton of glass recycled, 1300 pounds of sand, 410 pounds of soda ash, and 380 pounds of limestone are saved. This significantly reduces manufacturing costs and energy consumption, allowing us to offer economically priced products to our customers, including for their orders of custom glass bottles.

2 – Melting Raw Materials in the Furnace

The raw materials and cullet are continuously melted at extremely high temperatures, around 1650°C (3000°F), in a furnace that operates 24 hours a day. It takes approximately 24 hours for the mixture to transform into molten glass. This molten glass flows through a 'forehearth' (channel), and at the end of this channel, the glass stream is precisely cut into 'gobs' of a specific weight and temperature, ready for the forming of various types of containers, including custom glass bottles.

3 – Forming Glass Bottles/Jars

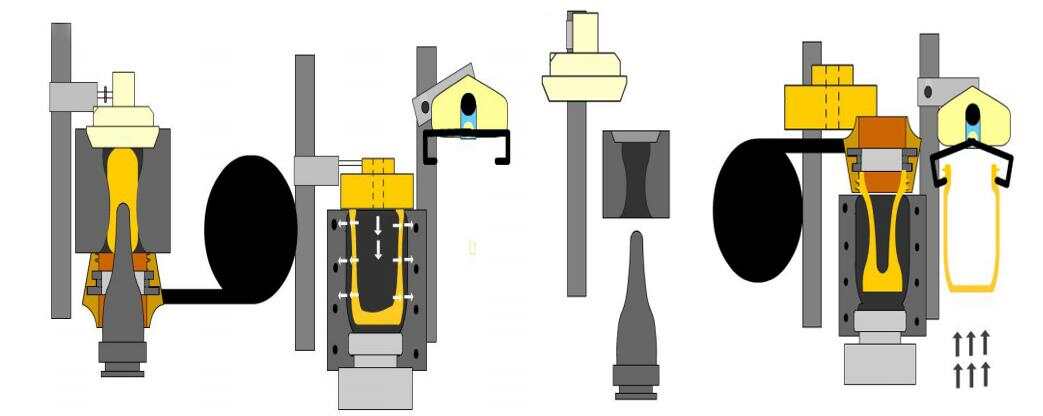

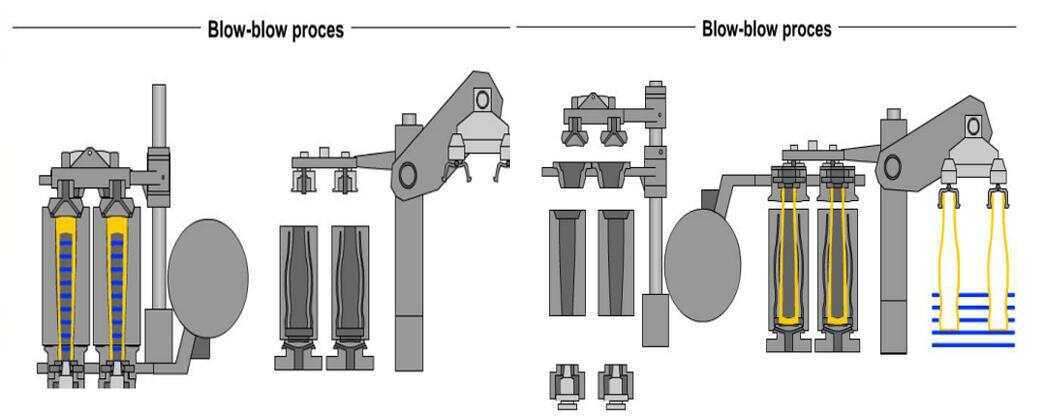

Two main forming methods are employed in an IS (Individual Section) machine to create the desired shape of the glass containers. This stage is crucial for shaping custom glass bottles to exact specifications.

4 – Annealing in the Glass Bottle Manufacturing Process

Regardless of the forming process, once the glass containers are shaped, they often undergo a surface coating treatment while still hot. This 'hot-end treatment' makes the bottles and jars more scratch-resistant. The newly formed glass bottles, including any custom glass bottles, are then conveyed through an annealing lehr. Here, their temperature is initially raised to around 815°C (1500°F) and then gradually reduced to below 480°C (900°F) over approximately 2 hours. This reheating and slow cooling process relieves internal stresses within the container, significantly enhancing the strength of the glass. Without annealing, the glass would be brittle and prone to shattering.

5 – Quality Inspection of Glass Bottles

Before final inspection, a 'cold-end surface coating' is often applied once the temperature of the glass containers has dropped to around 100°C (212°F). This further protects the glass from scratching.

After exiting the annealing lehr's cold end, we employ advanced technology to ensure the quality of every bottle. This is especially crucial for custom glass bottles that must meet precise client specifications. Our inspection includes:

LED light beam technology (LED inspection)

Camera inspection machines

Comprehensive inspection machines to detect faults invisible to the naked eye.

These checks cover, but are not limited to: sealing surface inspection, dimensional analysis, wall thickness measurement, detection of cracks or chips (breakage detection), side and bottom scanning, and wall scanning. Any bottle not meeting the strict standards is automatically rejected and sent back to be remelted as cullet. This automated inspection guarantees consistent, high-quality products for our customers.

6 – Packaging Glass Bottles

The packaging method for glass bottles, including custom glass bottles, will depend on customer requirements. Typically, we use two main methods:

Standard Pallet Packaging (Bulk Pack): Bottles are stacked on pallets, often with layer pads in between.

Carton Pallet Packaging (Case Pack): Bottles are packed into cartons, which are then stacked on pallets.

After the entire manufacturing process, the finished glass bottles are stored according to their required shapes and sizes, ready to be shipped to filling plants.